For anyone in the market for a business aircraft, the cockpit is a critical feature to evaluate. Modern integrated flight decks featuring fly-by-wire technology are becoming more common, offering enhanced safety, reduced pilot workload, and unprecedented situational awareness. Understanding these next-generation systems is crucial for any potential buyer, whether you’re acquiring a brand-new jet or seeking a used business jet with the latest technology.

WHAT IS FLY-BY-WIRE?

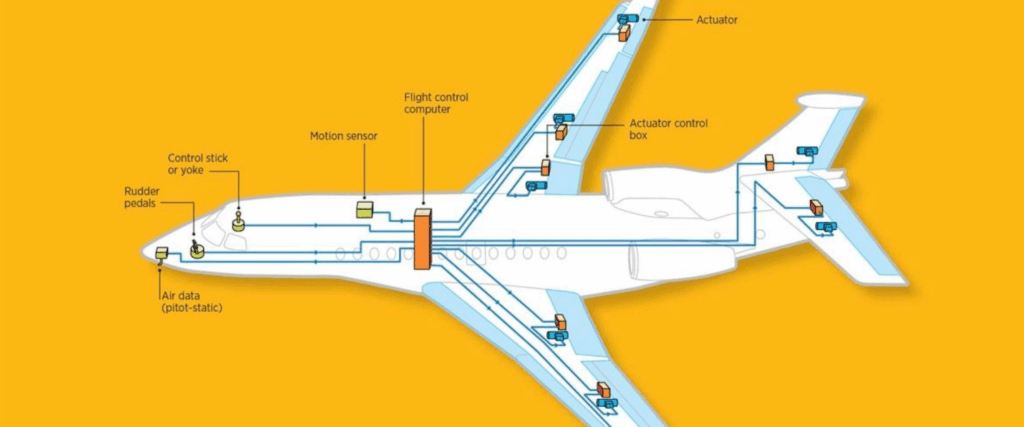

At its core, a fly-by-wire (FBW) system replaces the traditional mechanical linkages (cables, pulleys, and rods) connecting the pilot’s controls to the aircraft’s control surfaces (ailerons, rudder, and elevators). In a fly-by-wire aircraft, the pilot’s control inputs are converted into electronic signals, which are then processed by flight control computers (FCCs). The FCCs interpret these commands and send corresponding electrical signals to the control surface actuators, which then move the control surfaces accordingly.

THE BENEFITS OF FLY-BY-WIRE

- Enhanced Safety with Flight Envelope Protection

One of the most significant advantages of fly-by-wire is the integration of flight envelope protection. The FCCs constantly monitor aircraft parameters and pilot inputs to ensure the aircraft remains within its safe operating limits.

- Stall prevention: The system can automatically prevent a pilot from stalling the aircraft, even if they pull back too hard on the controls.

- Overspeed and G-force limiting: Fly-by-wire protects the aircraft from excessive speeds and structural stress by automatically adjusting control inputs to keep the aircraft within its operational limits.

- Disorientation protection: The system can prevent the pilot from inadvertently entering a dangerous flight attitude, such as an excessive bank angle, which is a major contributor to loss-of-control accidents.

2. REDUCED PILOT WORKLOAD AND IMPROVED EFFICIENCY

By taking over the management of complex flight parameters, fly-by-wire allows pilots to focus on strategic flight management rather than manual manipulation.

- Automatic trimming: The computer constantly makes micro-adjustments to keep the aircraft stable, eliminating the need for the pilot to manually trim the aircraft.

- Streamlined cockpit: The absence of mechanical linkages, pulleys, and cables allows for a cleaner, more streamlined cockpit design and easier integration with other advanced avionics.

- Consistent handling: Fly-by-wire ensures consistent handling characteristics across a wide range of speeds and flight conditions, resulting in a smoother, more predictable flight experience.

3. REDUCED WEIGHT AND MAINTENANCE

Replacing heavy mechanical components with lightweight electrical wiring provides several practical advantages.

- Improved fuel efficiency: The weight savings can translate into improved fuel efficiency, lowering overall operating costs.

- Lower maintenance: Electronic systems have fewer moving parts and are less prone to wear and tear than traditional mechanical linkages. Built-in test equipment (BITE) helps quickly detect and isolate failed components, allowing for more rapid repairs and reduced maintenance man-hours.

4. INCREASED DESIGN FLEXIBILITY

The move away from mechanical controls gives engineers more freedom in aircraft design.

- Aerodynamic efficiency: By relaxing the aircraft’s natural stability, engineers can design aircraft with better maneuverability and greater fuel efficiency, with the fly-by-wire system handling the necessary corrections to maintain stability.

- Optimized control: The system can be programmed to optimize control surface movements for maximum efficiency in various situations, such as extending flaps and adjusting the engines during a tight turn.

MAKING A STRATEGIC CHOICE

When considering a business aircraft acquisition, opting for a fly-by-wire equipped aircraft is a forward-thinking decision. For those looking to buy a used business jet, a fly-by-wire system is a significant value-add, offering not only advanced safety features but also enhanced operational efficiency and lower maintenance costs over the aircraft’s lifespan. It’s a technology that ensures smoother flights, reduced pilot workload, and a safer, more reliable experience for every passenger onboard.

At Holstein Aviation, our IADA certified professionals bring decades of transaction experience, real-time market intelligence and global reach. We guide our clients through every step of the process, ensuring confidence and clarity in today’s dynamic environment. One element of that process is evaluating various models of aircraft and the pros and cons of the systems installed on those aircraft. If you’re preparing to sell your aircraft or buy an aircraft, Holstein Aviation is your trusted partner in business aviation.